Problems and solutions for the mobility of vinyl rolls

In a signmaking or digital print shop, working with large rolls of vinyl is continuous, and their mobility and storage are critical. Thus, one of the problems faced by workshops is having little space available to carry out all the tasks of the different departments.

Main problems when working with large format vinyl rolls

Space constraints make it difficult to move and store vinyl rolls inside the print shops. This is a very common problem that generates frustration, clutter and delays in delivery times.

Today's end customers in the graphics industry require immediate and high-quality jobs. In order to meet the demands of the market, the best option will be to ‘go digital’ and solve the production delays that are due to the lack of correct equipment.

For example, during printing and post-press stages, vinyl and banner rolls must go through printers, laminators, welders, cutting tables and other finishing machines such as eyelet setting machines.

Another problem related to the mobility of rolls is their weight and size. In some cases, rolls exceed the standard length of 50 meters and become difficult for operators to handle.

In industrial workshops where the level of production requires a night shift and where there are usually fewer operators to change rolls, mobility problems increase. So as to improve safety and speed up processes, solutions that allow a single person to perform changes and movements are needed, such as roll lifters.

Problems and risks for workers at large format print shops

It is possible to find three specific problems:

Physical problems of the operator: having to make a great effort to handle heavy rolls in confined spaces can cause chronic injuries. Physical problems are not only suffered by the operator, since the company will also have to face sick leaves.

Waste of time: when more than two people are needed to move materials or rolls, the resources available at the workshop are wasted.

Loss of resources: having to handle materials in small areas with limited mobility possibilities increases the risk of bumps, breakage and damage to the material during transport.

Transporting Solutions for vinyl rolls

Improving the mobility and storage of print shops means a major change in tidiness and workflow, and a transformation towards the optimization of printing departments.

The roll holders for media storage and roll lifters are solutions that help to eliminate the problems and risks that we explained in the previous point. They can be used either for car wrap vinyl or meter vinyl at digital printing workshops.

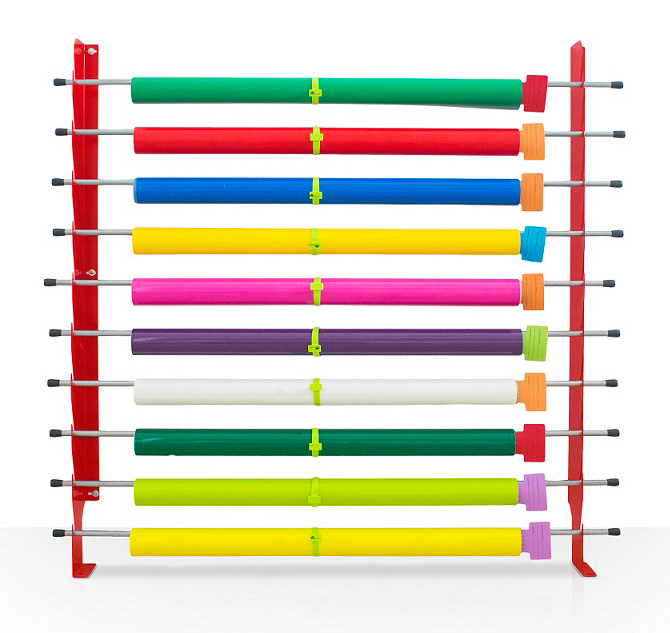

Media storage racks

In order to store and sort materials correctly and also to be able to transport them easily, at PLASTGrommet we offer several possibilities that adapt to the different needs that workshops may have. Next, we will see the most popular models:

BullRack: It is a horizontally-arranged mobile rack that facilitates the removal of rolls, allowing the storage of 15 rolls in very little space. Cutting can be done on the rack itself, with an optional cutter, without having to move it for different rolls. Its main advantage is that it has wheels, allowing storage and transport at the same time. Many customers place several of these racks in a row to optimize their space and then they take them out according to their needs.

WallRack: If the workshop is small and space is very limited, a perfect option to save space is to use walls as storage. Using walls to store vinyl is possible with this modular solution. You can keep tidy as many vinyl rolls as you want, and it also includes fixings to the floor for greater stability.

Easy Rack: it is an ergonomic solution that facilitates not only the storage and transport of media rolls but also the loading and unloading in an easy way since it has a folding hinge system that prevents the overexertion of the operators. In addition, it has a convenient handle with which you can perform maneuvers in small spaces easily.

BullRack XXL: in the case of large-format print shops, at PLASTGrommet we have an option for large rolls, up to 3.2 meters. It can store up to 8 rolls with a maximum outer diameter of 18 cm. Despite its great size, it is possible to move it around the finishing areas since it is mounted on wheels.

Other solutions: Depending on the needs of each workshop, we have other models of vinyl storage racks that include locking wheels for easy handling.

Vinyl Roll Lifters

As we have seen before, lifters are the perfect solution for handling heavy rolls in small spaces, even passing through doors with ease.

At PLASTGrommet we have two models of roll lifters: the QuickLifter, a battery-operated lifter, with which it is possible to load rolls of up to 150 kg and 3.2 meters, and the Compact Lifter, a hydraulic lifter for loading rolls of up to 200 kg and 5 meters wide.

These systems improve the productivity of printing shop workers, and they also prevent back injuries and health risks.

Solutions for roll storage

With the aim of keeping the media orderly in the print shop, it is necessary to identify them. Simply trying to distinguish them at sight will not work, as it is important to have an identifying control that allows us to make inventories in a fast and easy way.

In order to do this, we have Media cards that make it possible to find the labels or part numbers of the vinyl rolls in a suitable way.

To prevent rolls from unwinding, there are Roll Clips that do not damage the media. Adhesive tapes are becoming obsolete since they damage the material.

If you need more information about our products for vinyl signage, do not hesitate to contact us.

Latest news

Carretera Font Roja 23 03801 Alcoy (Alicante) SPAIN

Carretera Font Roja 23 03801 Alcoy (Alicante) SPAIN Youtube channel

Youtube channel LinkedIn

LinkedIn