The Finishing Station

|

The Finishing StationWelding & EyeletingFinishing station for banners with welding and eyeleting The ultimate banner finishing station. A single operator can operate the Finishing Station to completely finish rolls and banners with welding and eyeleting in ONE STEP.

|

The machine that print finishing operators have been waiting for: Hem welding & eyeletting in a single process.

- Unique built-in station with an automatic eyelet machine and a hot air welder.

- Banner finishing has never been so easy. Double pedal to control the operation, one to start/stop welding and the other for eyelet setting.

- Driven bottom synchronized rollers for consistent pressure.

- It is possible to do hem welding or just eyeletting as both machines are mounted on linear guides and can be stepped back.

- Optional conveyor system synchronized with the driven rollers for easy material handling.

Welding & Eyeleting in ONE step for any print shop

Eyeleting

|

The main task for which the Finishin Station is designed is the banner finishing process with welding and eyeleting in one step. To do this, we have installed our most advanced automatic eyelet machine, the Multipress. |

|

|

MultipressMultipress has been designed with large volume users in mind, it is fast (electric), reliable (washer and eyelet detector), features a double washer raceway, it can work with fabrics as well as PVC banners and it will inform you when maintenance is due, a must have for companies finishing large number of banners. It can work with different types of materials: fabrics, corrugated plastics, clear foil, PVC banners… |

Welding

|

Different welding options. With "The Finishing Station" you can finish your banners using keder, tap reforcement or hem welding. Welding and Eyeleting at the same time is possible using this station. |

|

|

Top-of-the-range hot air blower:

|

It is possible to do hem welding or just eyeletting as both machines are mounted on linear guides and can be stepped back

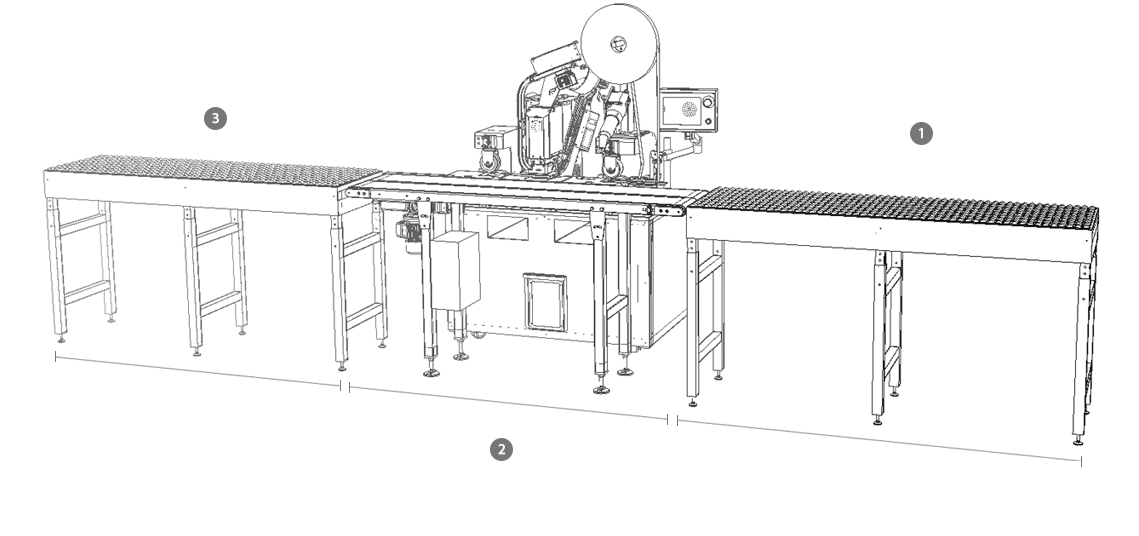

Technologies and Features

1. Positioning and welding pedal | 2. Waste deposit | 3.Conveyor belt | 4. Welder | 5. Touch screen | 6. Tape dispenser

7. Eyelet and washer dispenser | 8. Eyelet machine | 9. Banner traction system | 10. Extension Table

Tables

We have two types of tables. A conveyor belt that is driven when you drive the machine. And a Extension Table that can be put before and after the conveyor belt.

Conveyor Belt: An automatic action table that will provide you with the best help and comfort to work. This table is connected and synchronized with the Finishing Station.

Extension Tables: Auxiliary table designed to be placed before and after the conveyor belt.

Contact us

The Finishing StationWelding & Eyeleting |

With us, your company is covered

Guarantee |

Technical Support |

Reliability |

Safety first |

+34 965 339 969

+34 965 339 969

Carretera Font Roja 23 03801 Alcoy (Alicante) SPAIN

Carretera Font Roja 23 03801 Alcoy (Alicante) SPAIN Youtube channel

Youtube channel LinkedIn

LinkedIn