Probo case study

Innovation, Automation and Expansion All In One

|

|

Download pdf version |

How Probo streamlines wide-format banner finishing with PLASTGrommet

|

Probo, a trade printer with facilities in the Netherlands, Belgium, and Germany, is a business with innovation at its core. |

|

|

As Probo continues to grow, it’s important that the investment in new machinery is in keeping with their innovative approach. “Probo’s approach to selecting new equipment aligns with the principles of Industry 5.0, where automation, human creativity, and sustainability intersect to create a smarter and more efficient production environment,” says Jordy de Jong, Marketing and Business Development Manager, Probo. |

|

Experiencing automation in action

|

When Probo first discovered PLASTGrommet’s finishing solutions, they were looking at ways to boost capacity in order to deliver products to customers faster and at a better price. “We first encountered PLASTGrommet at FESPA 2021 in Amsterdam,” says Jordy. “After seeing the All In One machine in action, we were very interested, and started the quotation process.” |

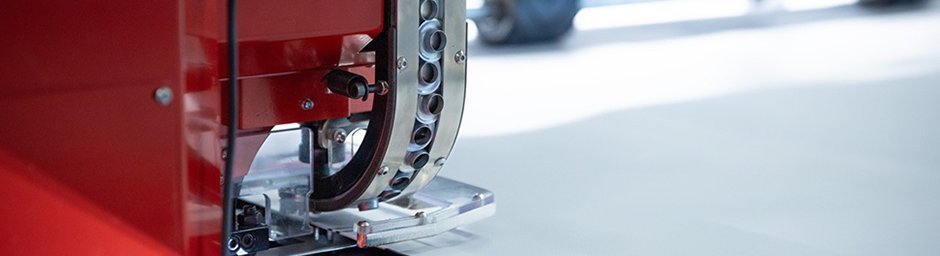

Key features include an automatic roll edge alignment system, a vision system for precise eyelet and cut mark reading, and industrial-grade hot air welders capable of 24/7 operation. In 2022, Probo took delivery of the All In One at its Dokkum location, and haven’t looked back since. |

|

The All In One from PLASTGrommet is a cuttingedge automated solution for large-format banner finishing, seamlessly integrating welding, eyeleting, and cutting into a single efficient process. Designed with productivity in mind, the All In One reduces lead times and labour costs while conserving valuable floor space. |

Probo’s All In One configuration offers a choice of four fixed formats; 100cm, 150cm, 175cm, and 200cm, and gives customer the option of a hemming or hemming and rings finish. “Communication from PLASTGrommet was very strong and well structured. They were extremely eager to get everything right the first time. There were thorough training sessions for both the operators and the technical team.” |

"Over the years, I’ve overseen many installations and implementations, and I can confidently say that the installation and implementation of this project was among the best."

|

Outlining the seamless workflow integration process, Jordy continues: “Orders from Probo.nl that qualify for the All in One are automatically intercepted from Pre-press, with the platform recognising the standard widths. The orders are then collected and grouped by standard banner width. Afterward, our planning team schedules the orders on a specific printer, and the printed roll goes to the All in One. "PLASTGrommet provides timely and effective support, ensuring their technology runs seamlessly in our production. Their proactive communication, quick issue resolution, and expert guidance help us maintain the high standards our print professionals expect. This reliable partnership strengthens our ability to deliver quality, speed, and innovation." |

|

Targeting new markets with All In One

Since instalment, Probo’s experience with the All In One from PLASTGrommet has continued to reap benefits, as Jordy explains: “The investment in the PLASTGrommet finishing machine has significantly impacted Probo’s business by increasing the share of wallet with our existing print professionals.

Previously, print professionals relied on Probo for low-volume barrier banners, thanks to our flexibility and quality. With the introduction of the All In One, we are now able to offer competitive solutions for high-volume orders as well. This dual capability—serving both low and high volumes—ensures that customers can consolidate all their barrier banner needs with Probo, rather than sourcing high volumes elsewhere.”

The positive impact of the All In One is evident from the customer response. Previously, many Probo customers expressed regret that they could not order high-volume barrier banners at a desirable price point. “The market for construction banners has experienced a huge growth. A lot of print professionals are buying these products in high volume in low wage countries, and at Probo we believed we could provide better products for this market.

Probo has received enthusiastic feedback from customers regarding the benefits of the PLASTGrommet finishing machine,” says Jordy, adding: “With this new capability, customers are now thrilled to consolidate all their orders with Probo. We’ve seen a significant improvement in lead times, enabling us to guarantee delivery times for our customers.”

A sustainable future for print

Minimising waste across the value chain with smart production techniques is at the forefront of Probo’s principles. In 2022, the company reinforced its commitment to circular innovation, launching Sign Again, the first 100 percent circular material made entirely from used banners and cutting waste.

“With local, on-demand production and circular solutions like Sign Again, we minimise environmental impact while maintaining the highest quality standards,” Jordy explains.

In 2024, Probo unveiled “Het Kompas,” its roadmap for innovation and sustainability, kicking off construction on a fully automated warehouse and giving Sign Again its own dedicated production space.

|

|

"One standout benefit of working with

PLASTGrommet is the ability to use PVCfree

plastic rings in our finishing process.

|

Continuing on a prosperous path

|

Since the relationship’s inception, the two companies have worked closely to highlight the synergy between Probo’s print production process and PLASTGrommet’s equipment, including at FESPA 2024 in Amsterdam, in a city in which Probo and PLASTGrommet first became acquainted at the 2021 show, where Sign Again was highlighted on the PLASTGrommet stand. Looking ahead, as Probo always does, the relationship between Probo and PLASTGrommet is set to continue to thrive. “We continue to focus heavily on automation, robotics, and AI, as these technologies drive efficiency, scalability, and sustainability. Any innovation that aligns with these priorities, including advancements from PLASTGrommet, is of great interest to us. We see PLASTGrommet as a valuable partner, and further investments in their technology are always on the table if it supports our mission of delivering cutting-edge solutions for our print professionals,” says Jordy. |

"This partnership shows how we collectively work toward a sustainable, innovative, and future-proof print industry-one that balances technology, creativity, and environmental responsibility." |

Download pdf version |

Carretera Font Roja 23 03801 Alcoy (Alicante) SPAIN

Carretera Font Roja 23 03801 Alcoy (Alicante) SPAIN Youtube channel

Youtube channel LinkedIn

LinkedIn