Roll2Roll

|

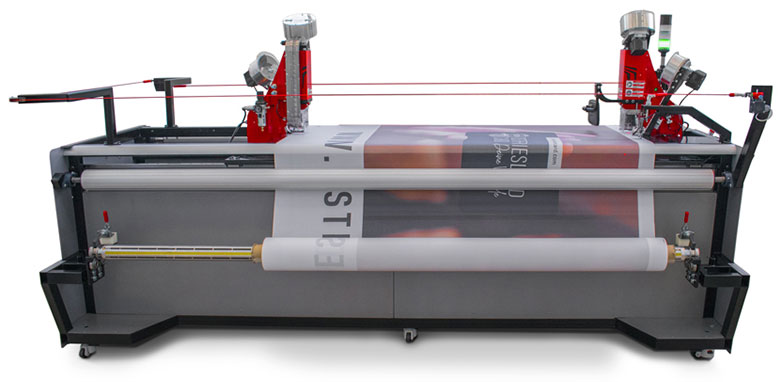

Roll2RollAutomate time-consuming finishing tasks with a reduced footprintThree different models to choose from depending on your specific finishing needs. |

Workflow is key to moving jobs through your shop efficiently and out the door to your customers.

Finishing is the bottleneck of print production and hiring and training staff takes time and can be expensive.

The new Roll2Roll range automates time-consuming tasks as welding and grommeting, with a reduced footprint.

Three different models to choose from depending on your specific finishing needs:

|

|

|

Manual slitting. |

Manual slitting. |

Motorized traction gantry. Automatic slitting. |

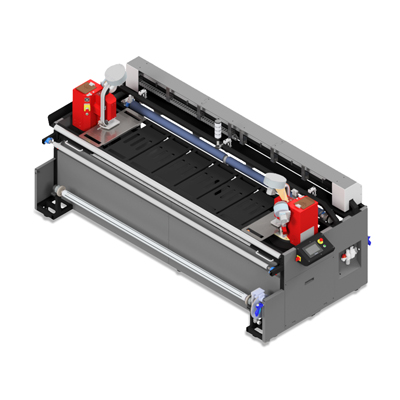

Roll2Roll WELDING

If you produce fence-mesh or banners on a roll, to weld 50 m or 100 m rolls is a difficult task for any print shop as rolls are heavy and difficult to handle.

Roll2Roll Welding automates the process of welding both sides of the roll simultaneously using hot air technology with low noise level compare with other systems.

If you are currently using pre-hemmed mesh, this product will offer a flexible finishing solution and you can upsell your jobs using webbing tape instead of hemming, offering a product with higher wind resistance.

Single flap keder is often welded using high-frequency technology, not the fastest process. Discover what productivity means with the special keder guide and keder dispenser.

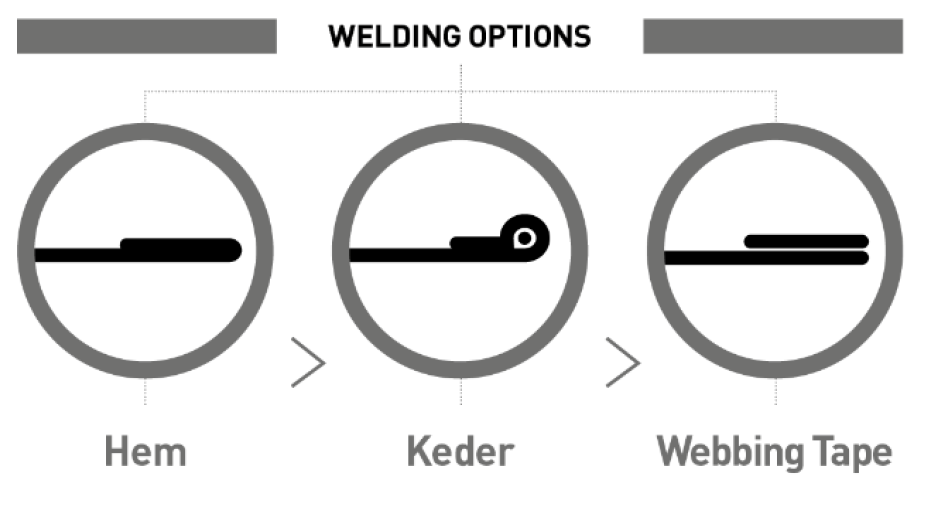

| WELDINGThree different welding options :

Machine is supplied as standard with hemming guides, others are optional.  |

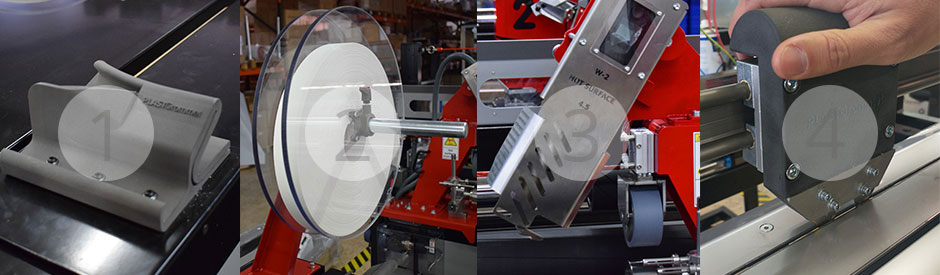

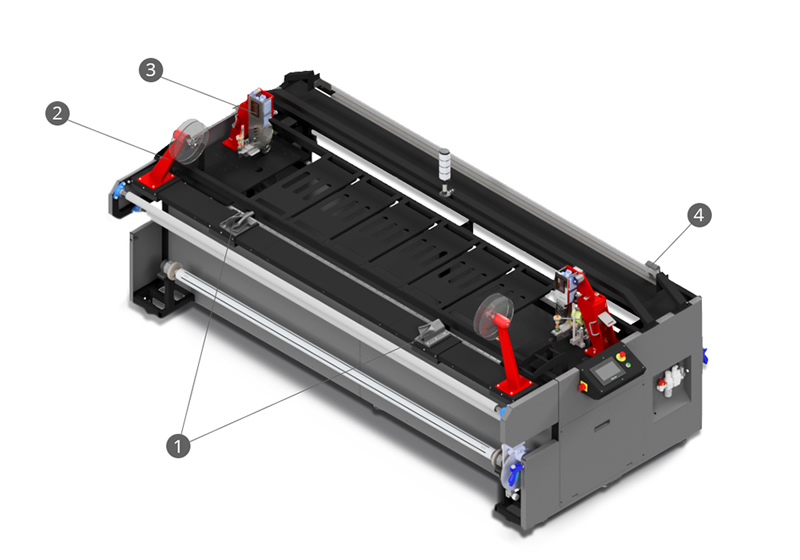

Technologies and Features

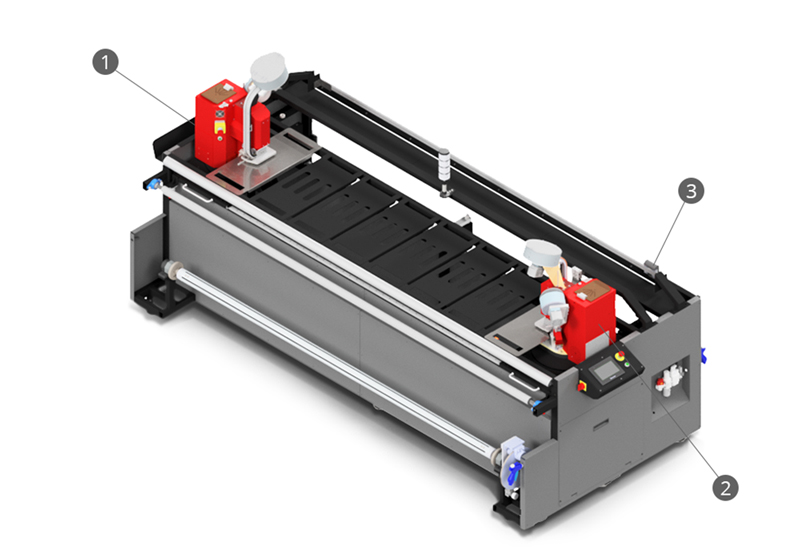

1. Pre-hemming guides | 2. Webbing tape dispenser | 3. Hot-air welder | 4. Manual slittier | 5. Keder dispenser (not shown in the picture)

Video

Roll2Roll EYELETING

Grommeting both sides of a roll is a time-consuming task if you do not have the correct equipment at your shop.

If you need to grommet both sides because you have welded the roll with Roll2Roll Welding, you are using pre-hemmed media or you n0eed to finish single layer banners, Roll2Roll Eyeleting is the machine you have been looking for.

Automatic grommet setting selecting distance between grommets (this figure will be constant for the entire roll).

| EYELETINGYou can choose between two grommet presses depending on your needs:

|

Independent grommet station

Automatic grommet machine

|

|

Technologies and Features

1. Grommet press 1 (turning 180º) | 2. Grommet press 2| 3. Manual slitter

Video

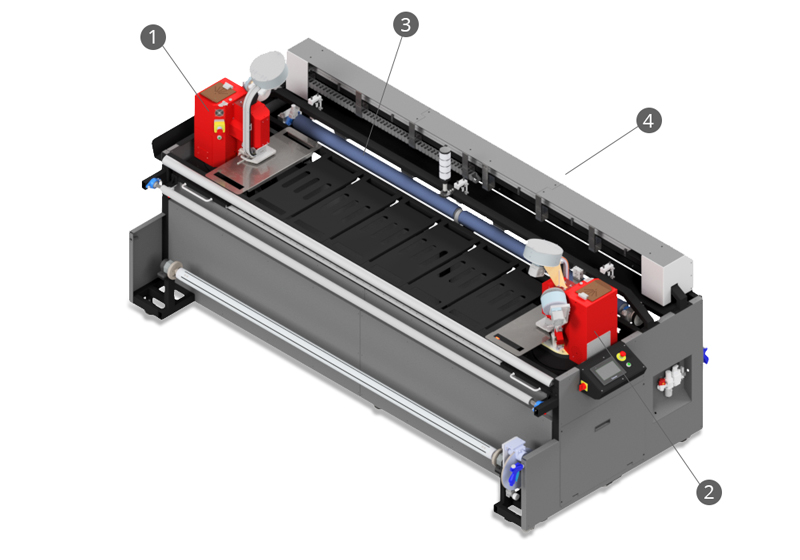

Roll2Roll EYELETING PRO

This machine has same features as Roll2Roll Eyeleting, incorporating a motorized traction gantry and an automatic slitting device. Roll2Roll Eyeleting Pro offers great flexibility in terms of finishing as you can grommet full rolls or grommet banners cut to a certain length. Precise control of the grommet and cutting position with the use of a servo motor.

| EYELETING + SLITTINGYou can choose between two grommet presses depending on your needs:

|

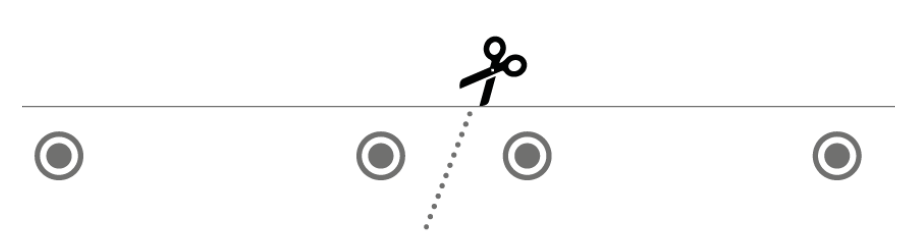

Mode: Roll to banner

When producing banners, it is possible to set two grommets together to slit between them (last grommet of one banner/first grommet of the other).

Technologies and Features

1. Grommet press 1 (turning 180º) | 2. Grommet press 2| 3. Traction gantry | 4. Automatic slitting

Video

Contact us

Roll2Roll

WELDING | EYELETING | EYELETING PRO

With us, your company is covered

Guarantee |

Technical Support |

Reliability |

Safety first |

>

+1 305 447 7040

+1 305 447 7040

2153 Coral Way, Suite 400, Miami, FL 33145 | USA

2153 Coral Way, Suite 400, Miami, FL 33145 | USA Youtube channel

Youtube channel LinkedIn

LinkedIn